In 2003, Mersudin Omerović initiated the design and development of products in the metal sector as a collaborator with other companies that had similar needs.

Read more...

Read more...

TOOL-MACHINE.team offers solutions for a wide range ofproduction that requires knowledge of technology and engineering connections.Our strength lies in innovative...

Read More...

Read More...

TOOL-MACHINE.team owes its continuous growth to close collaboration with long-term partners in various fields:

-Food Industry

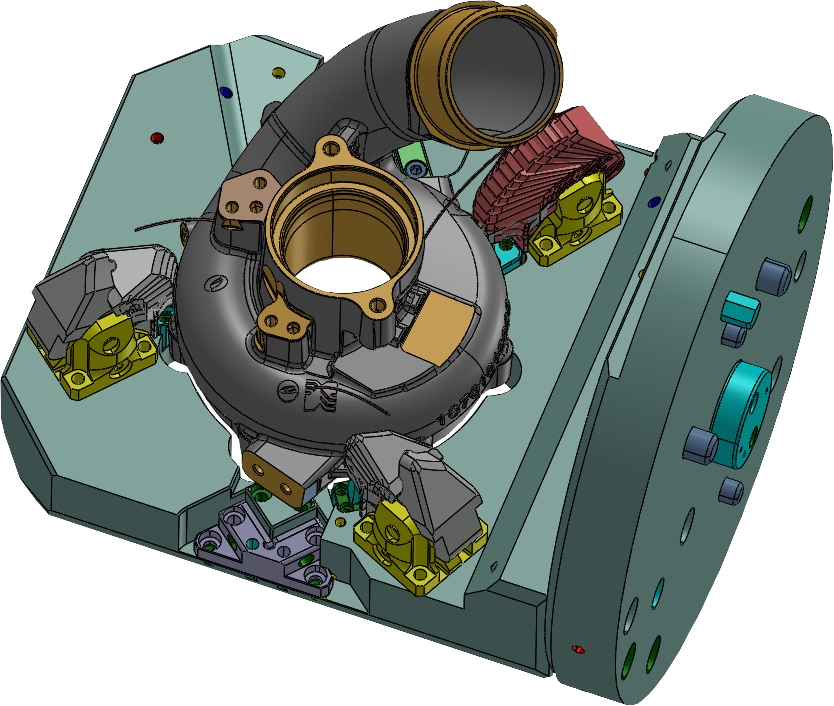

-Automotive Industry

-Military Industry

-Printing Industry

-Metal Industry

Our commitment to a green future. For us, sustainability is not a trend but an integral part of our culture. As a family business, we think long-term and look to future generations. Our fundamental understanding is based on the role of a responsible employer and a reputable business partner. This also includes...

Read More...

Read More...

...explore us better...

Explore us better. Learn how we build secure connectionswith customers and the demands of tomorrow.

Read more... Read More

Read More

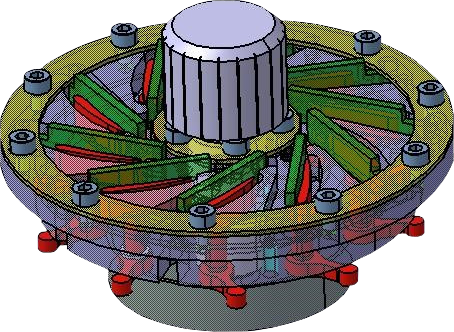

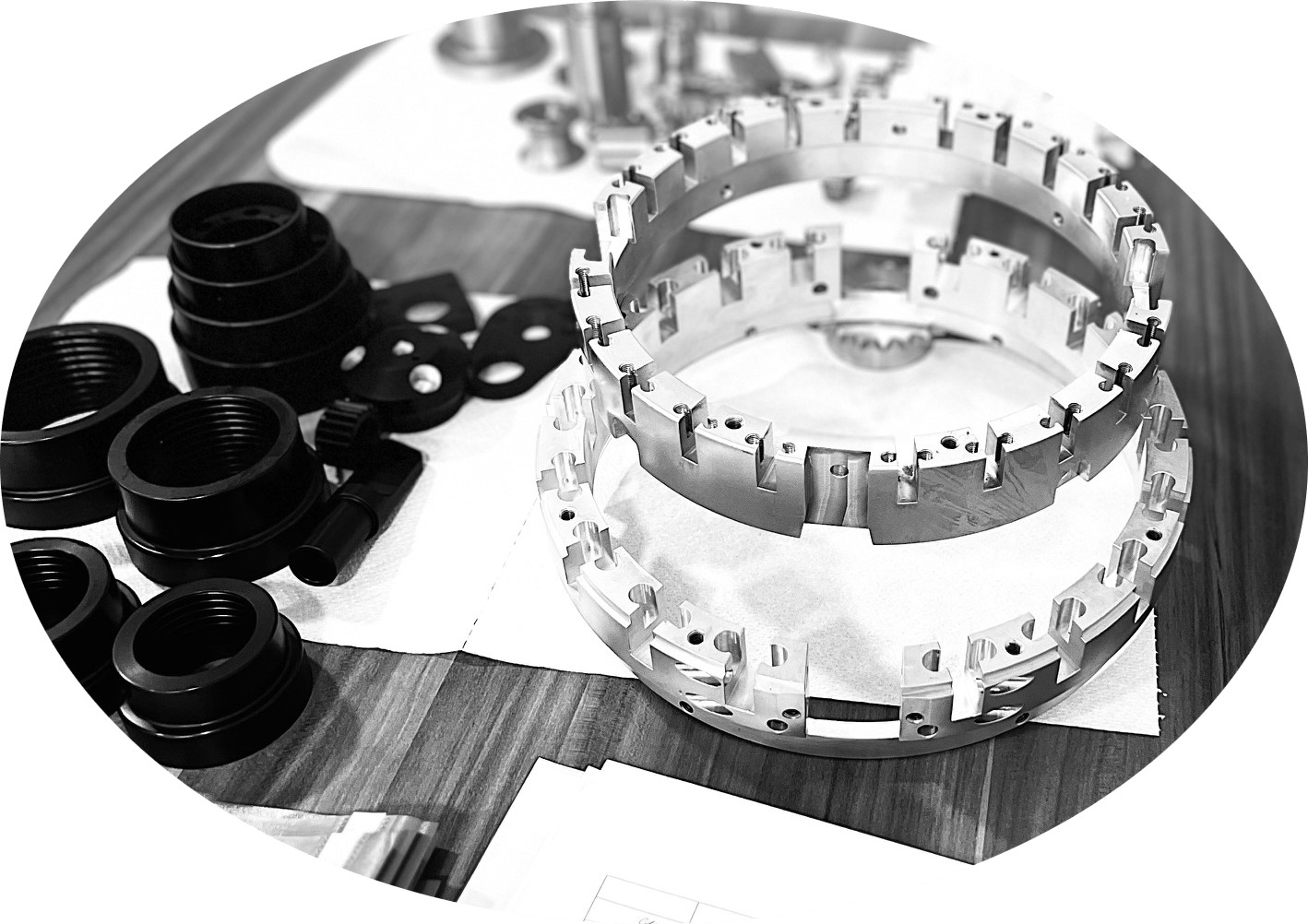

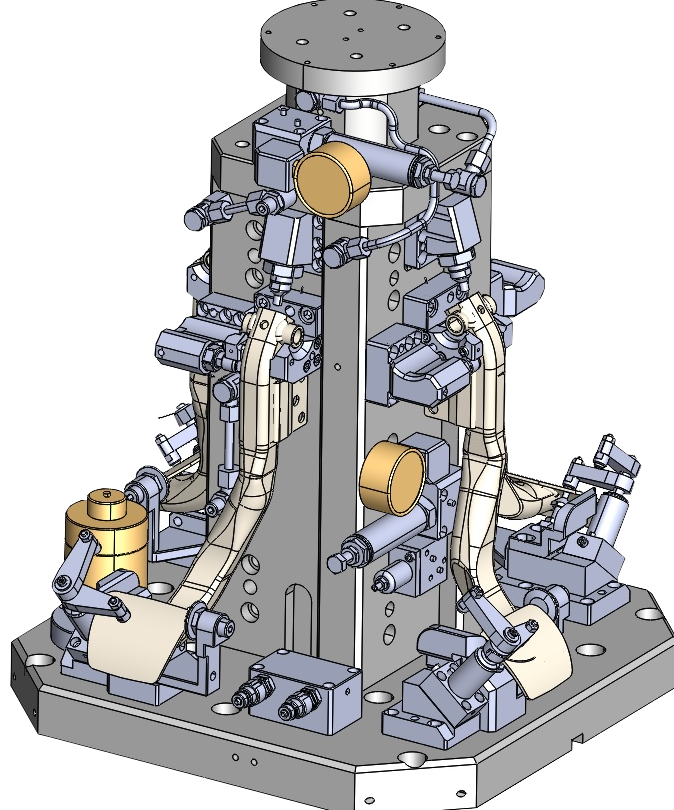

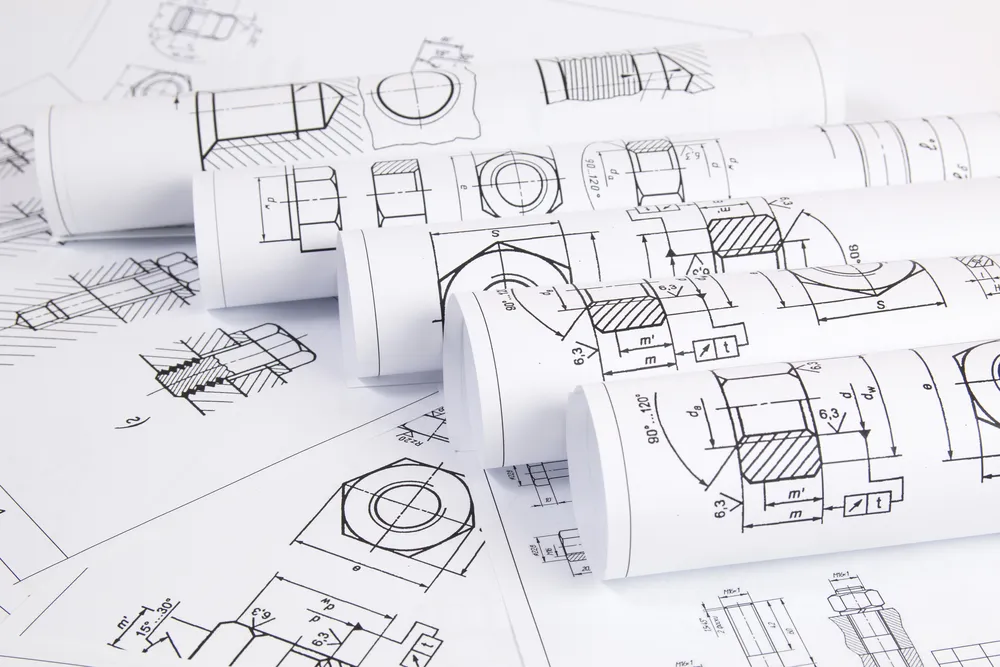

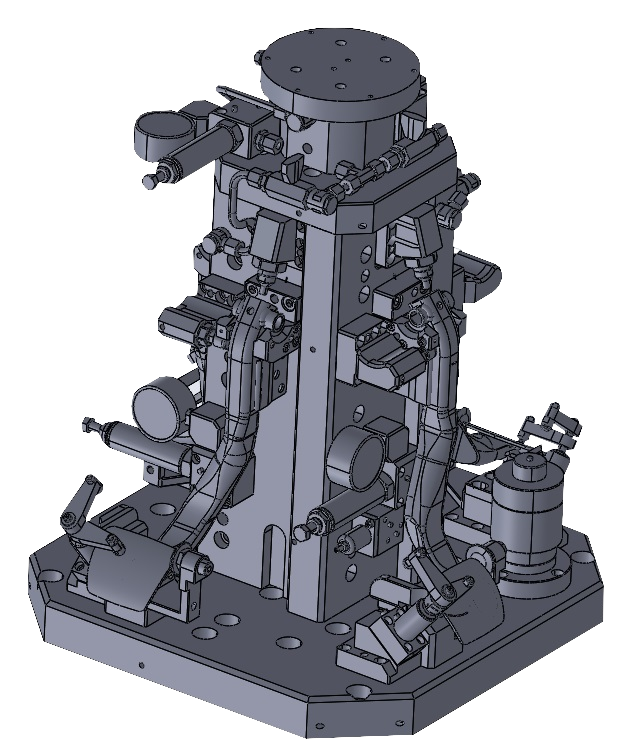

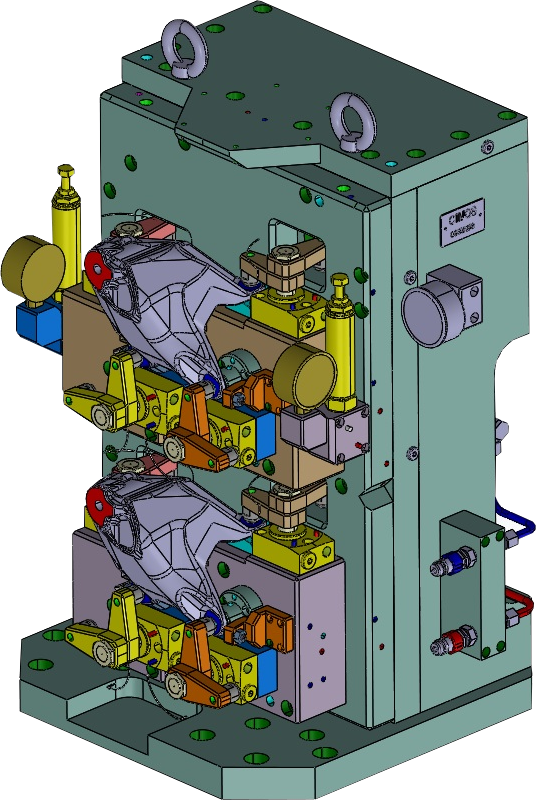

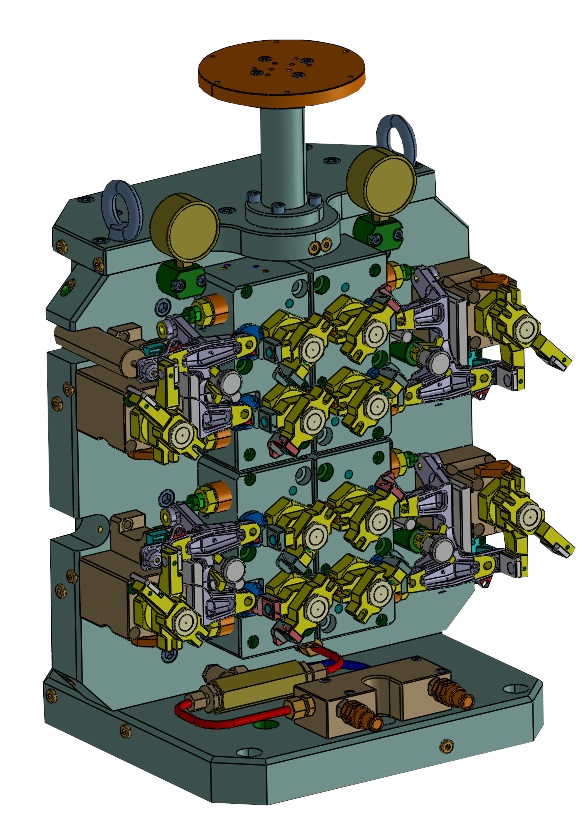

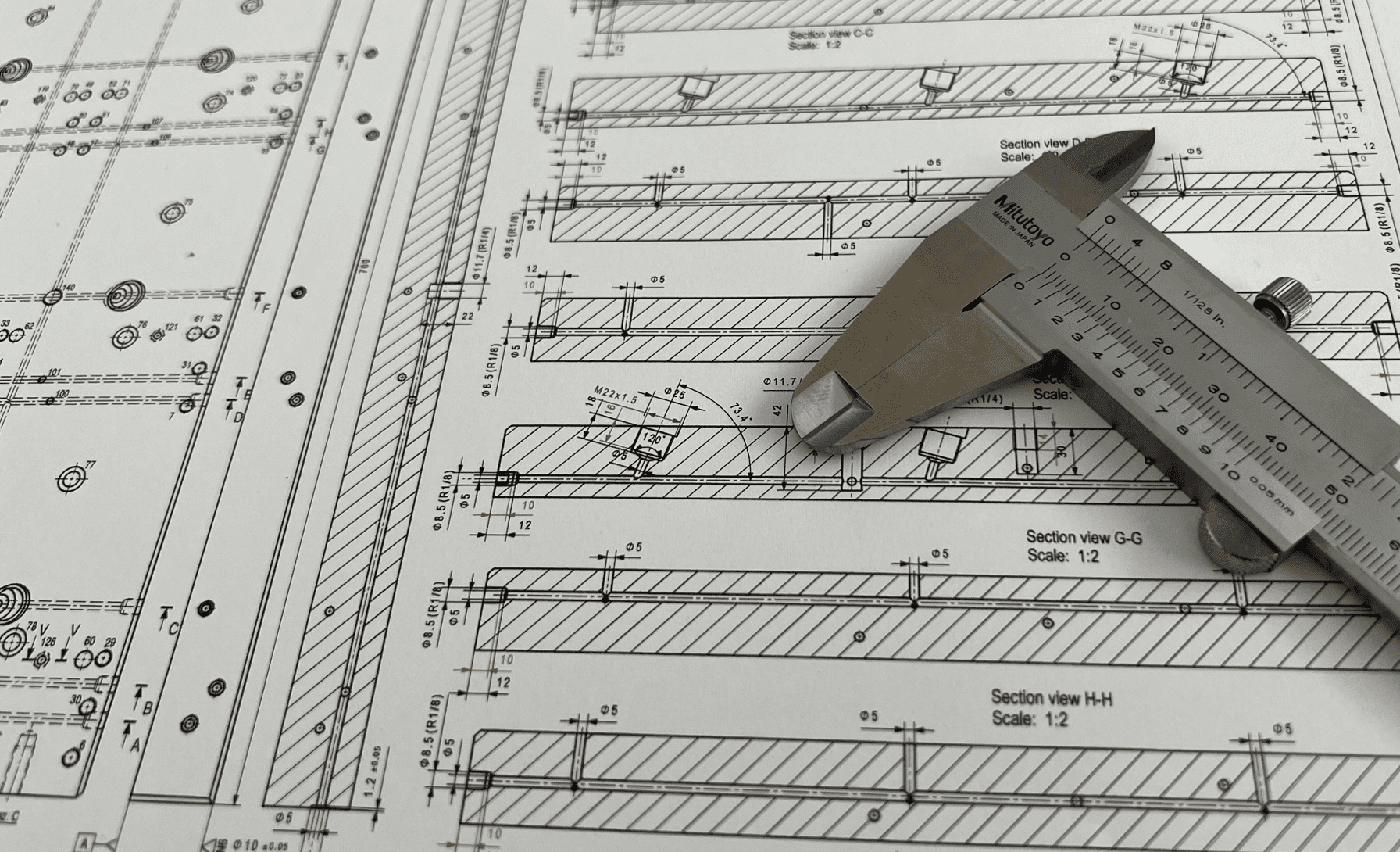

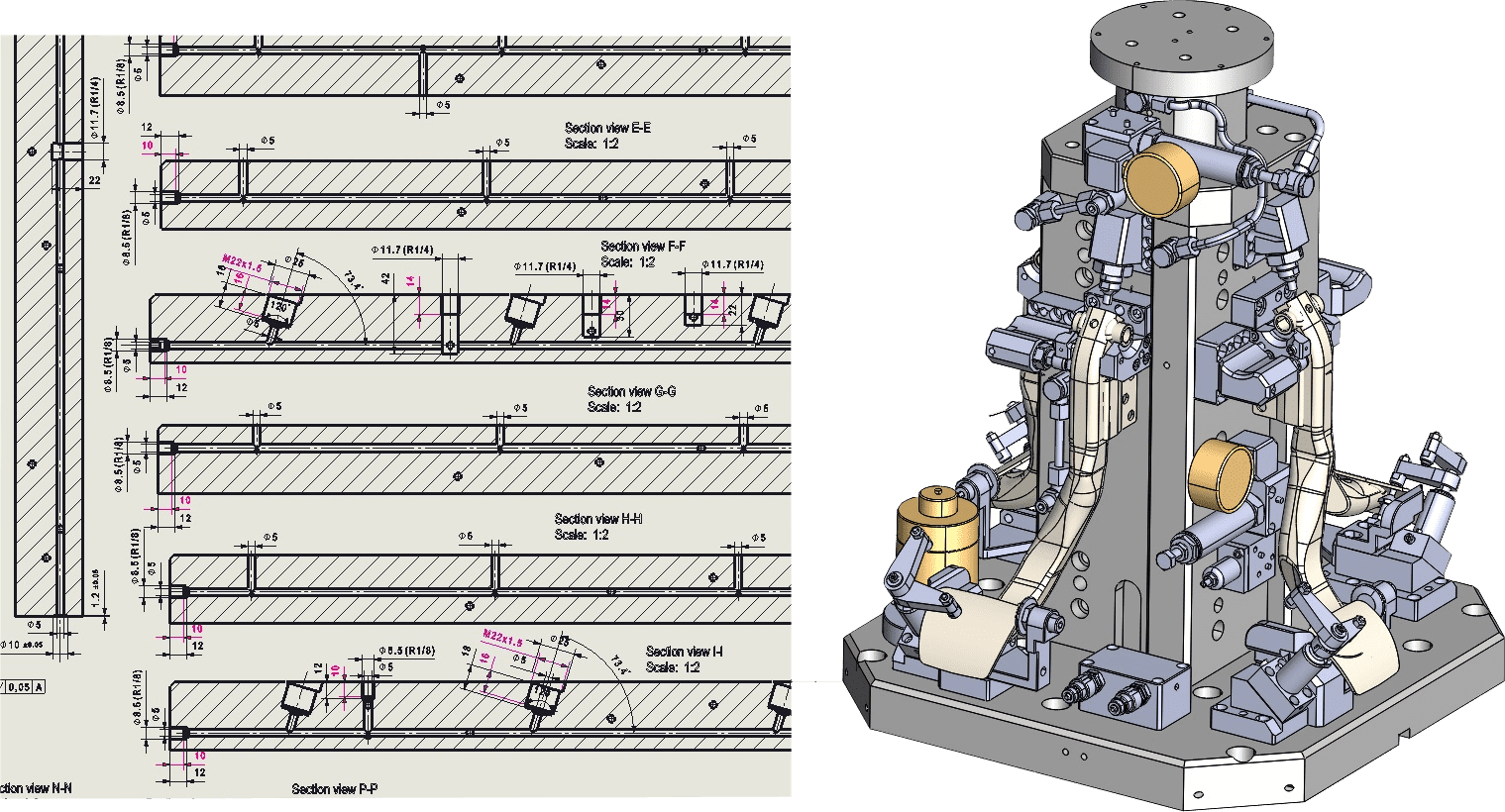

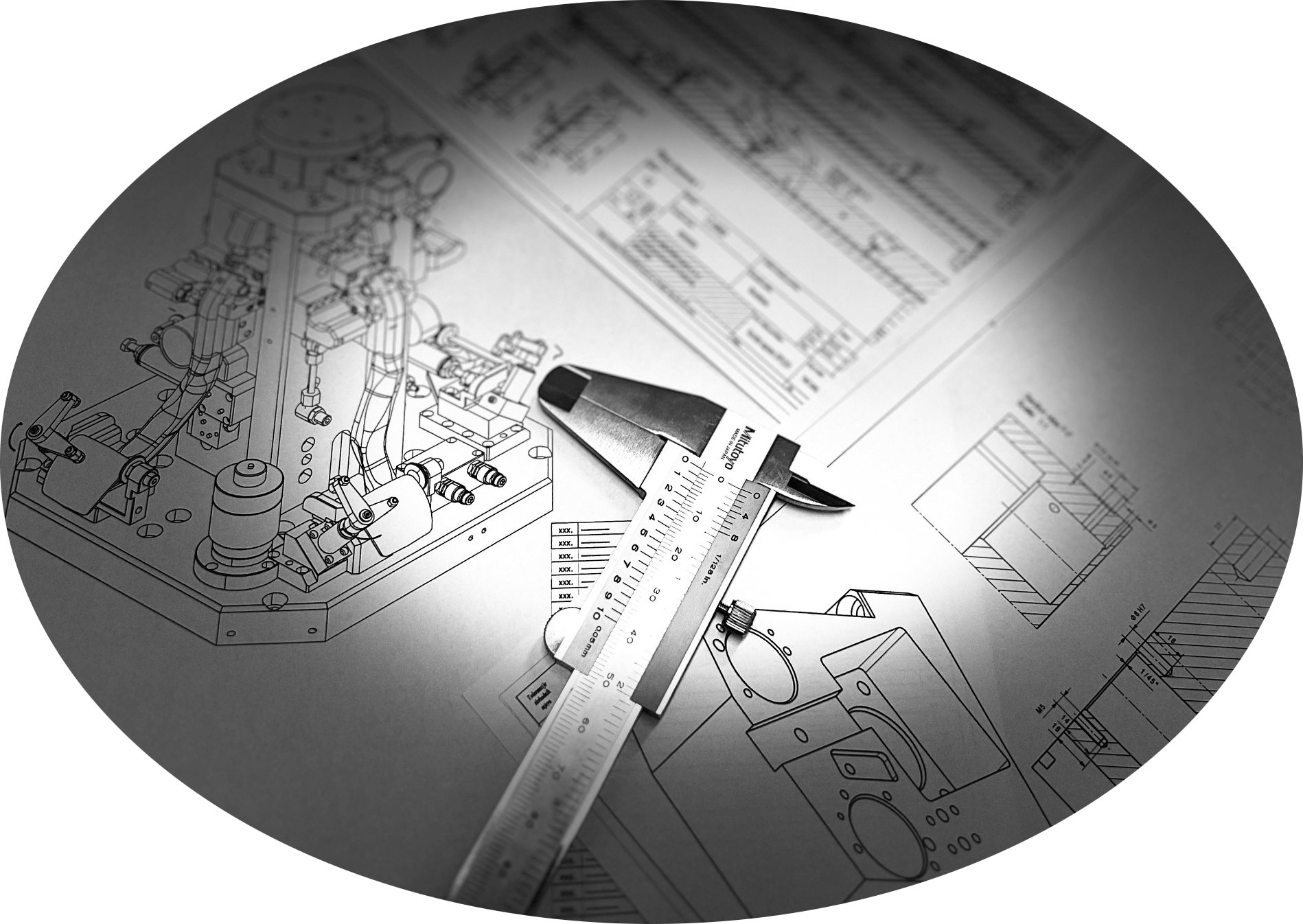

...development and design of products...

...our product development is supported by staff with professional experience...

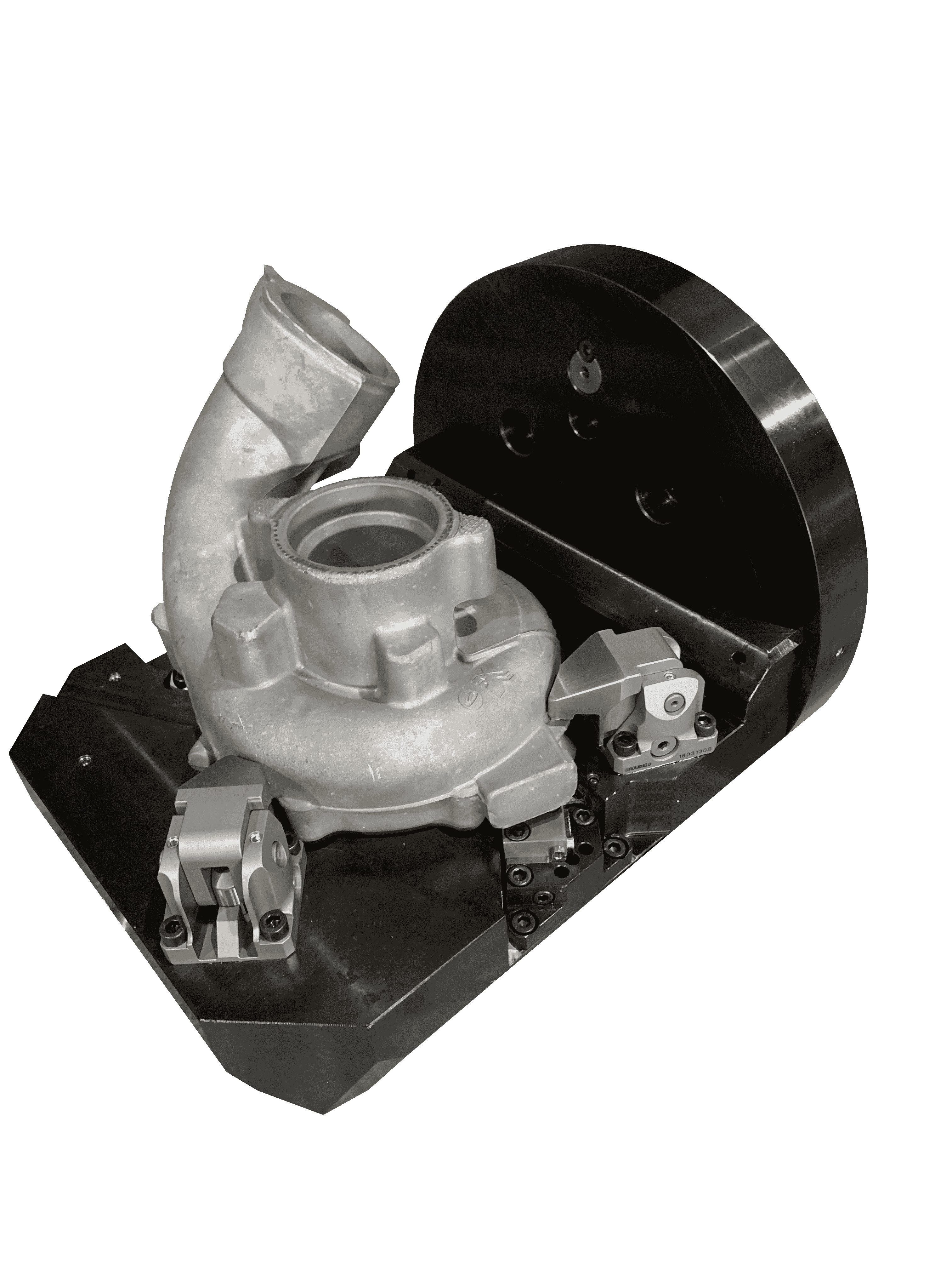

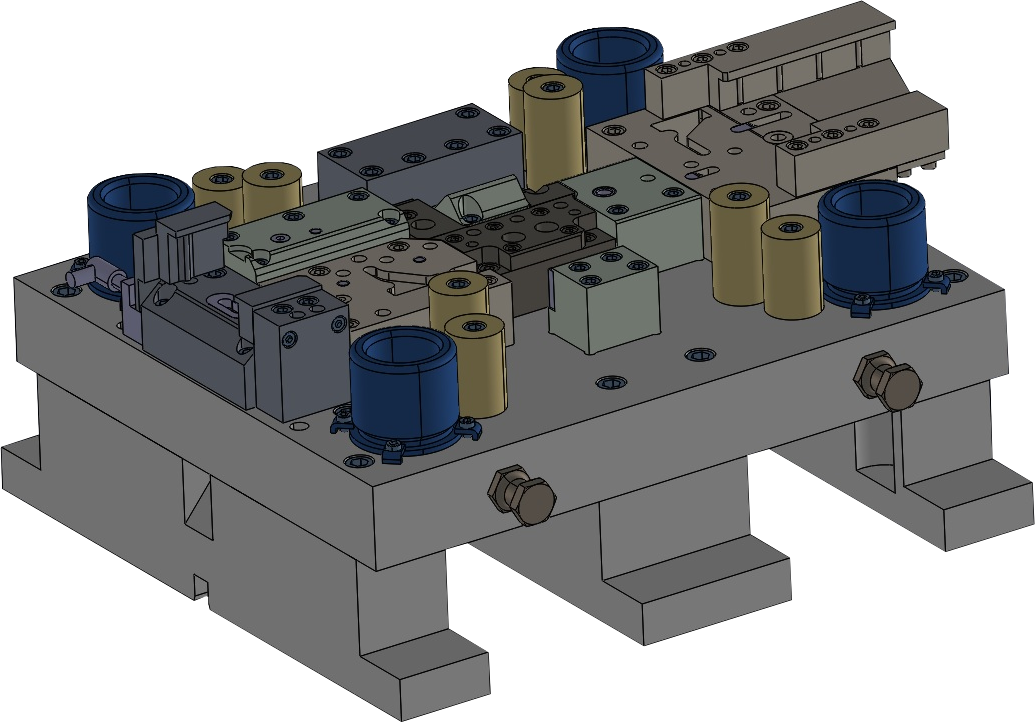

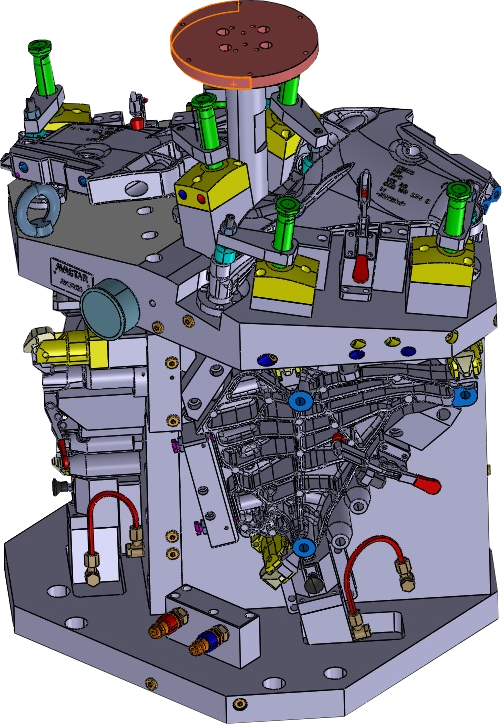

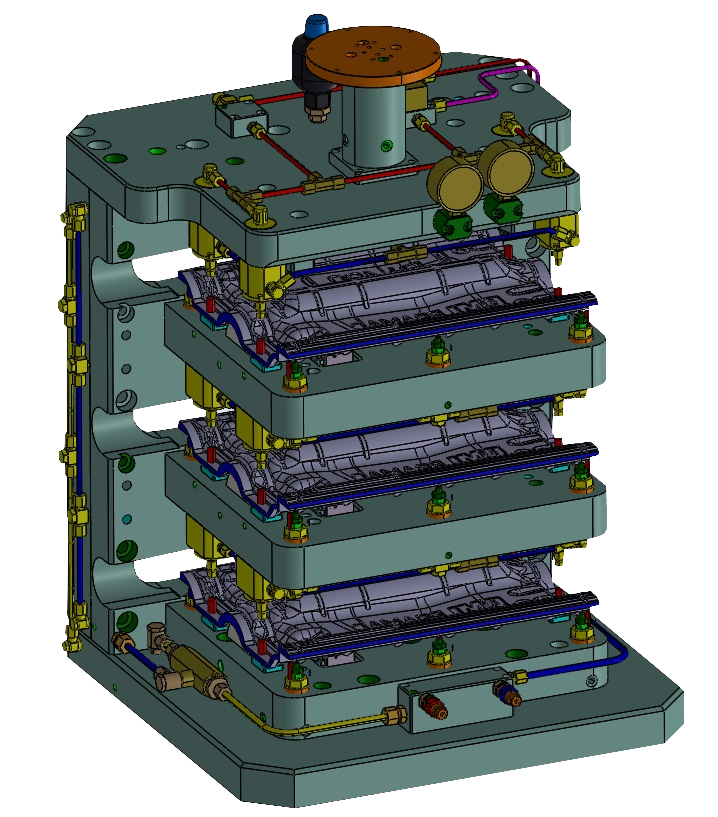

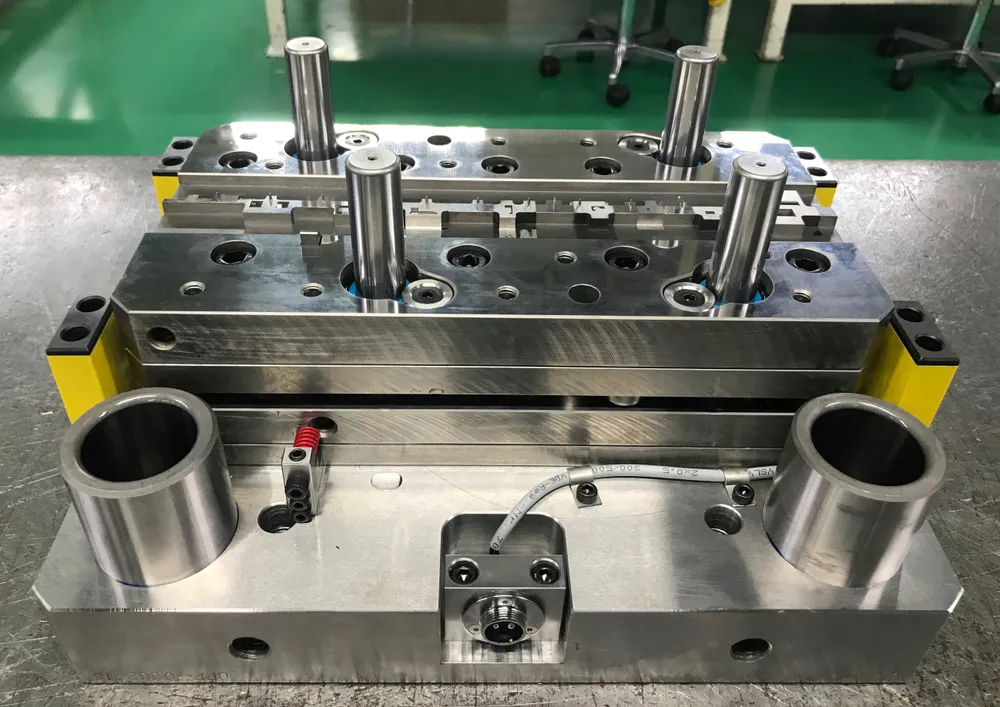

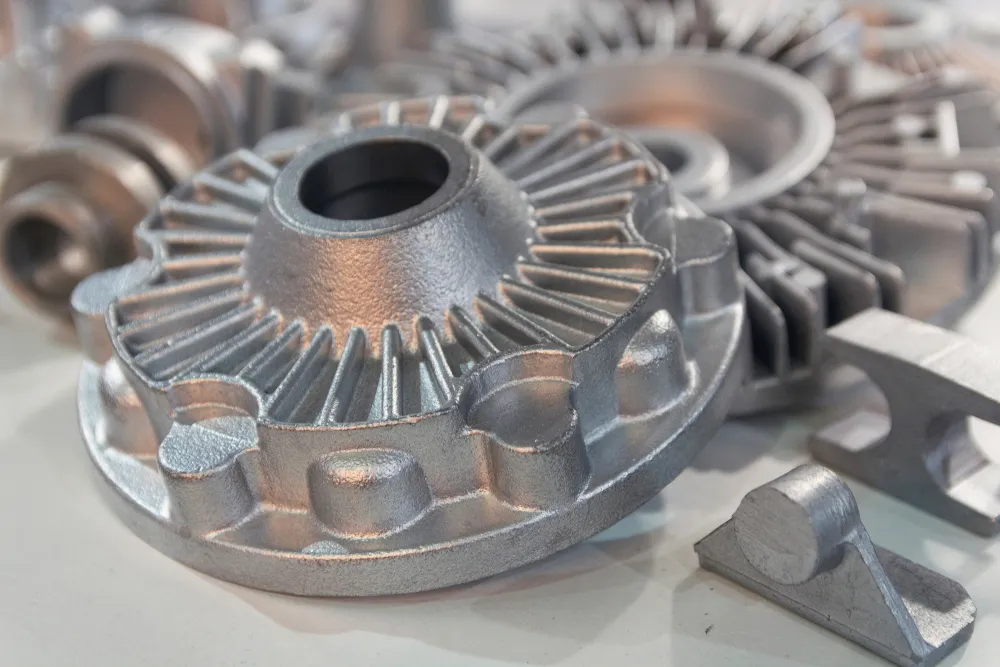

Read More......intelligent solutions for metal milling processes...

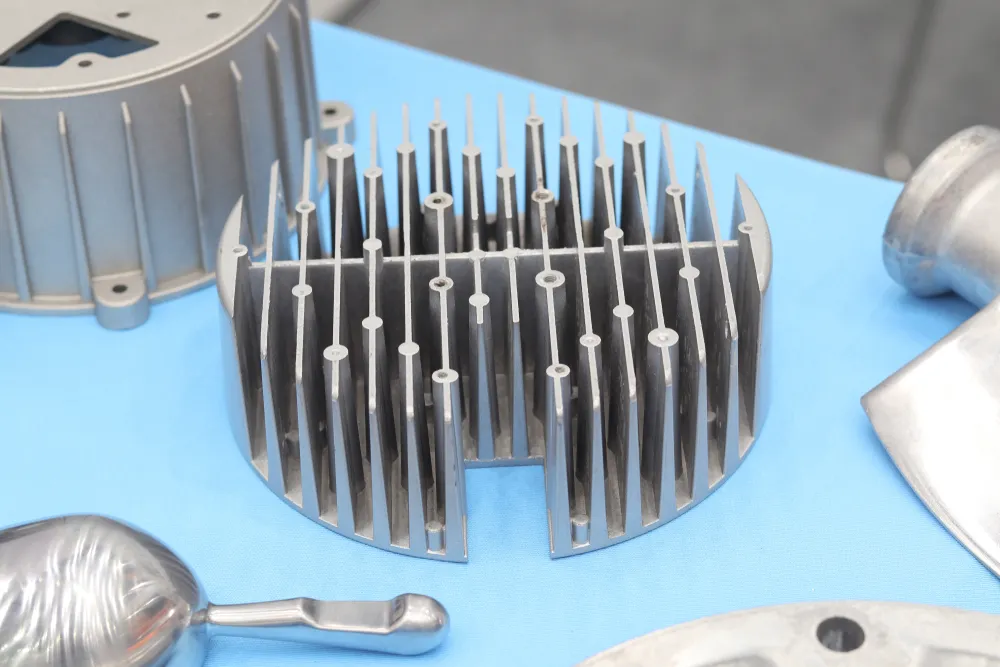

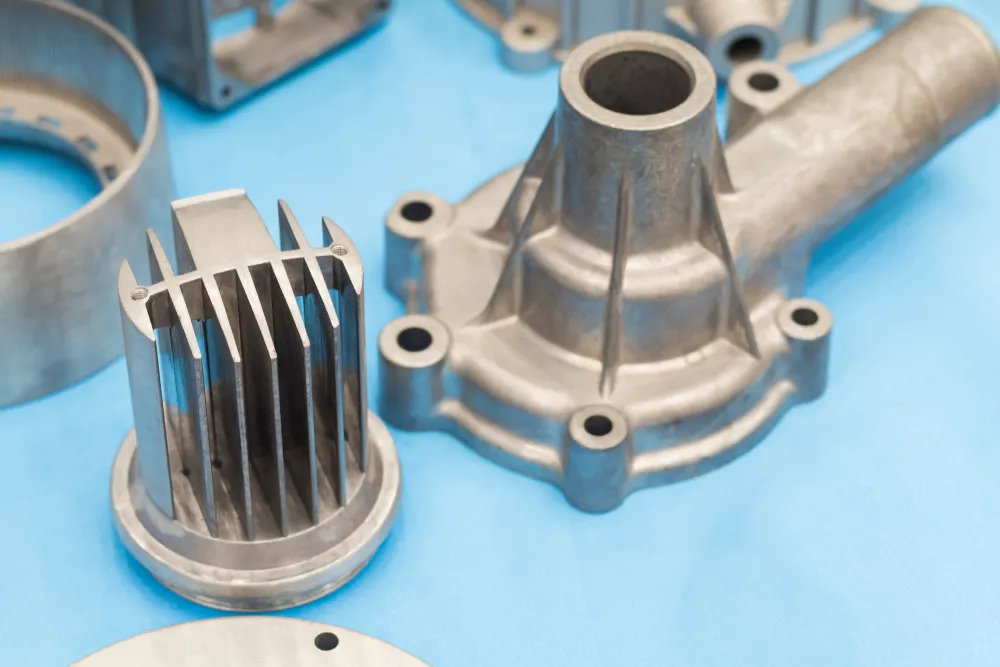

...quality and complex products are provided by modern processing centers...

Read More......optimal interventions in the turning process...

...we include single-spindle CNC lathes; CNC lathes with driven tools...

Read More......optimal interventions in the turning process...

...we achieve solutions for you with innovative methods...

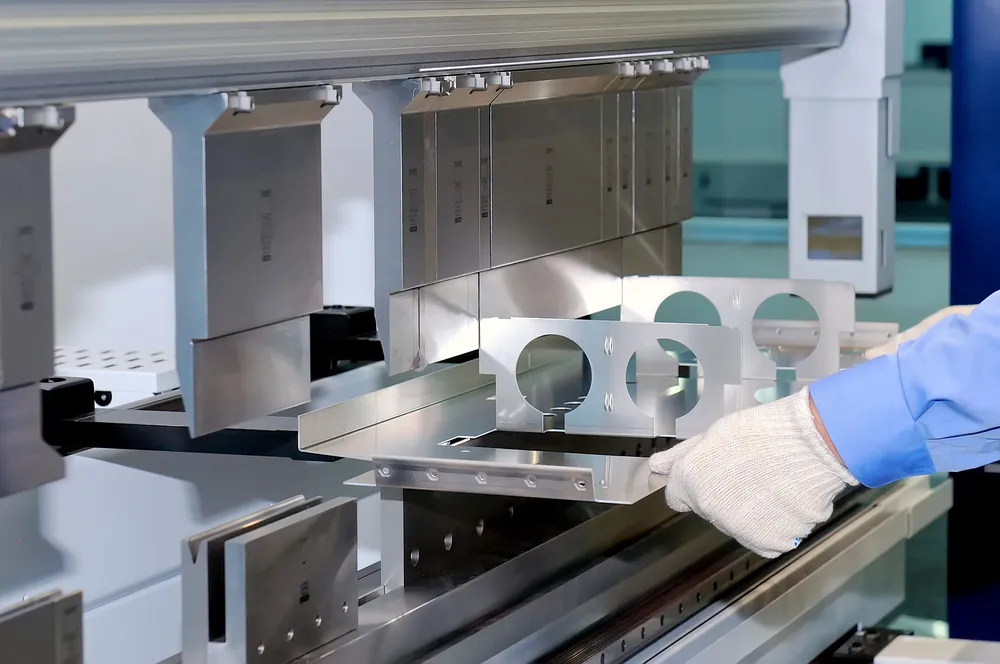

Read More......get to know our sheet metal processing methods...

...we achieve solutions for you with innovative methods...

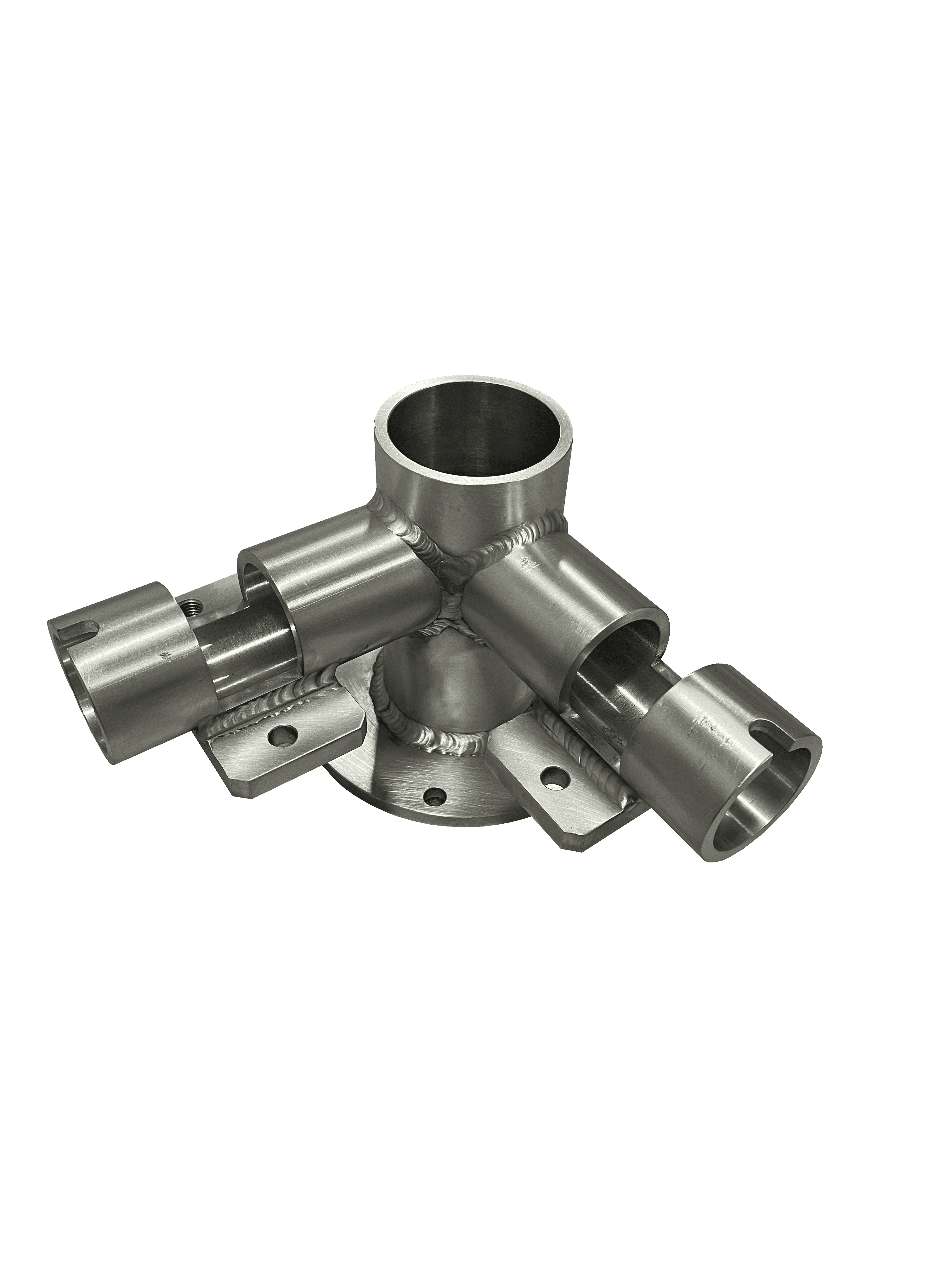

Read More......explore our welding capabilities...

...we offer Arc Welding processes such as MIG, MAG and TIG welding processes...

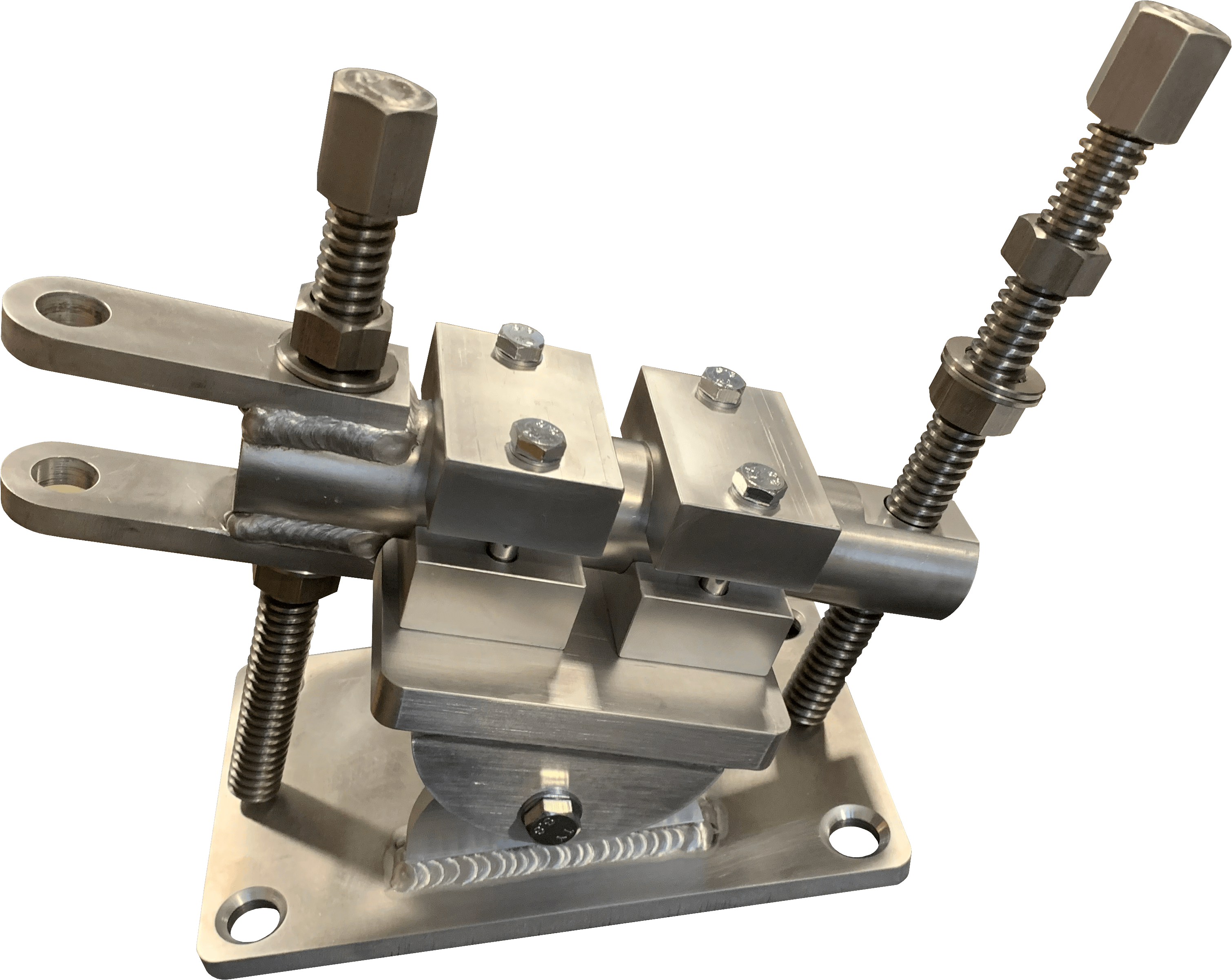

Read More......efficient assembly of assemblies as per customer requirements...

...test our assembly efficiency in our production facilities or at the customer's site...

Read More...

...assembly efficiency ensured by an efficient team...

...our team will meet your expectations...

Read More...